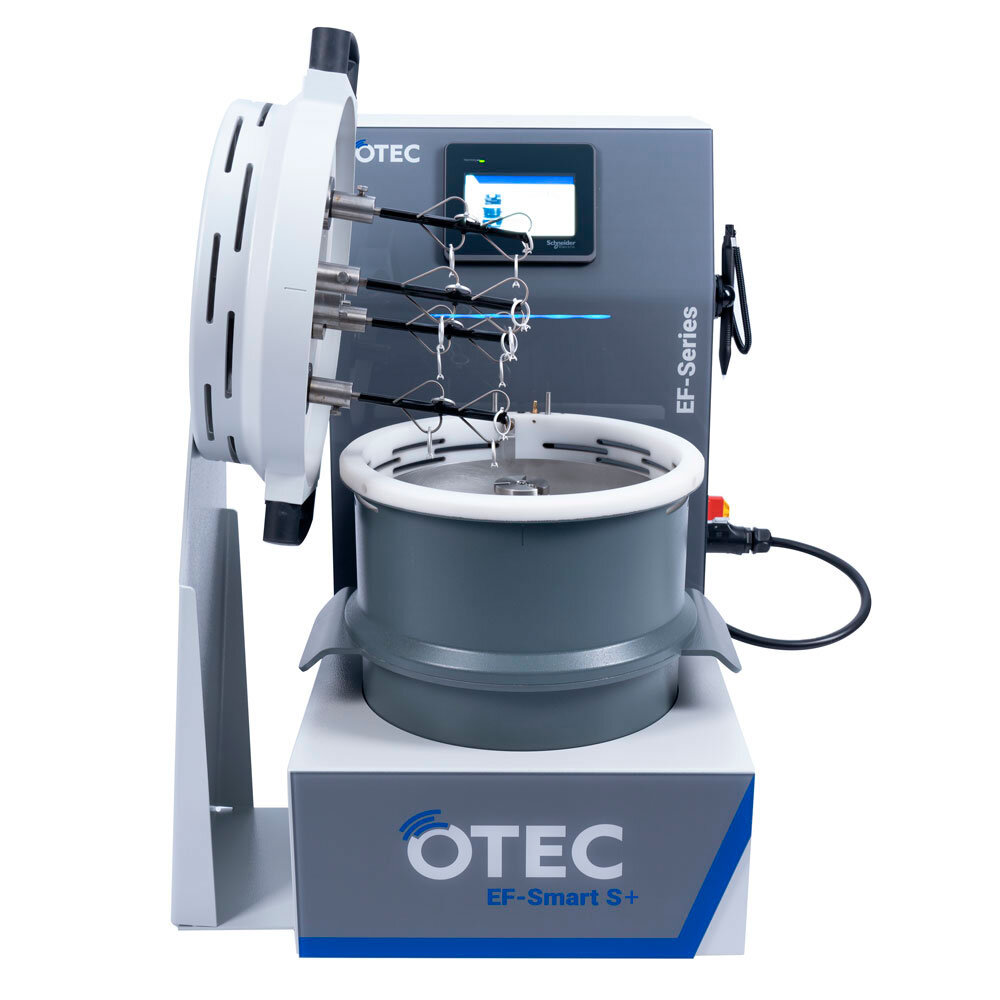

Electropolishing machine EF-Smart S+, OTEC

Description:

The EF-Smart S+ is an electropolishing machine developed for professionals who require uniform, reproducible surfaces – even on complex jewellery and delicate workpieces. The machine combines advanced electropolishing technology with high user-friendliness and an efficient workflow that significantly reduces manual finishing steps.

The EF-Smart S+ is particularly suitable for jewellery with fine details, internal contours and hard-to-reach areas, as well as stone-set pieces. The electrolytic process works gently and in a controlled manner, ensuring smooth surface finishing and a high-gloss polish without rounding settings or risking damage to gemstones. The result is top-quality finishes combined with short processing times and maximum process reliability.

The machine operates without acids or cyanide, supporting a safer and more considerate working environment. Programming is intuitive and makes it easy to set up and store multi-step processes based on direction of rotation, voltage, processing time and speed. This ensures consistent results, even in repeated production runs.

The EF-Smart S+ is supplied with one titanium cathode container (OT22110) for processing palladium white gold. An additional container with stainless steel cathode (OT22100) for gold and other alloys is available as an option. Containers can be changed quickly, allowing the machine to be converted between different materials in just minutes. At the same time, the cathode system enables efficient recovery of precious metals directly from the process.

With capacity for up to 24 workpieces at a time, the EF-Smart S+ is ideal for both one-off production and small series. The machine is equally suitable for cast jewellery and 3D-printed pieces, supporting a modern and efficient production workflow in the professional workshop.

- Compact electropolishing machine with ergonomic operation

- Gentle and uniform polishing of complex jewellery and stone-set pieces

- No use of acids or cyanide

- No pre-polishing required

- Effective processing of internal contours and hard-to-reach areas

- Intuitive programming of multi-step processes for reproducible results

- Fast changeover between different metals via interchangeable containers

- Efficient precious metal recovery via cathodes

- Suitable for both cast and 3D-printed jewellery

Specifications:

- Capacity: up to 24 workpieces per process

- Dimensions: 450 x 610 x 605 mm

- Weight: 45 kg

- Power supply: 230 V / 50–60 Hz