- Frontpage

-

New

Tilbage

Luk -

Tools & Machines

Tilbage

LukTools & Machines

-

Se alt i Tools & Machines

- New

-

Hand Tools

Tilbage

LukHand Tools

-

Se alt i Hand Tools

- Pliers

- Saw Frames & Blades

- Precisions Files / Handles for needle files

- Calipers / Measuring

- Dividers / Engineers Squares

- Magnifier / Glasses

- Shears

- Tweezers

- Soldering Tweezers / Third-hand

- Hammers

- Ring Sticks / Ring Gauges / Wrist Meters

- Joint Cutters / Profile Cutters

- Special Tools

- Reamers / Pin Vices

- Stamps

-

Drills / Cutters / Miniature brushes

Tilbage

LukDrills / Cutters / Miniature brushes

-

Grinding / Polishing

Tilbage

LukGrinding / Polishing

-

Engraving / Stone Setting

-

Metal Forming

Tilbage

Luk -

Soldering / Melting Equipment

Tilbage

Luk -

Machines

Tilbage

LukMachines

-

Se alt i Machines

- Electropolishing

- Electroplating

- Engraving Machines / Laser Engraving

- Compressors

- Magnetic Tumbler / Rotary Tumbler

- Micromotors / Flex Shaft motors

- Ring Stretchers / Ring Bending Machines

- Blasting

- Grinding / Polishing / Brass

- Pickling Units

- Draw Bench

- Extraction unit

- Ultrasonic Cleaners / Steam Jet Cleaners

- Rolling Mills

- Vivacolor

-

Wax / Casting

-

Literature

Tilbage

LukLiterature

-

Equipment

- Watchmaker Tools

-

Chemicals / Cleaning

Tilbage

Luk

-

Findings

Tilbage

LukFindings

-

Se alt i Findings

- New findings

-

Pearl Clasps / Parts

Tilbage

Luk -

Settings / Pendants

Tilbage

LukSettings / Pendants

-

Brooch

Tilbage

Luk -

Ear Parts

-

Cufflinks / Tie Clips / Tie Slides / Button Backs

Tilbage

LukCufflinks / Tie Clips / Tie Slides / Button Backs

-

Clasps

-

Chains

Tilbage

Luk -

Assorted Findings

Tilbage

Luk

-

Diamonds & Gemstones

Tilbage

LukDiamonds & Gemstones

-

Courses

- Log ind

- Min konto

- Log ud

-

Vælg sprog

Tilbage

LukVælg sprog

- Frontpage

- Tools & Machines

- Machines

- Rolling Mills

Rolling Mills

At Aktiv Guld, we offer a wide range of combi and special rolling mills specially developed for goldsmiths and jewellery designers. In our range you will find everything from small manual hand-operated rolling mills to large and powerful electric double motor rolling mills. We know how important it is to have the best tool and especially important is to have a high quality rolling mill that can deliver a professional result and do so for many decades to come. See our selection of professional rolling mills for jewellery making on this page. If you need advice and guidance, you are always welcome to contact us.

Filtrer efter

-

Electropolishing

- Electropolishing (24) Electroplating

- Electroplating (28) Engraving Machines / Laser Engraving

- Engraving Machines / Laser Engraving (42) Compressors

- Compressors (15) Magnetic Tumbler / Rotary Tumbler

- Magnetic Tumbler / Rotary Tumbler (63) Micromotors / Flex Shaft motors

- Micromotors / Flex Shaft motors (35) Ring Stretchers / Ring Bending Machines

- Ring Stretchers / Ring Bending Machines (8) Blasting

- Blasting (1) Grinding / Polishing / Brass

- Grinding / Polishing / Brass (23) Pickling Units

- Pickling Units (7) Draw Bench

- Draw Bench (9) Extraction unit

- Extraction unit (27) Ultrasonic Cleaners / Steam Jet Cleaners

- Ultrasonic Cleaners / Steam Jet Cleaners (29) Rolling Mills

- Rolling Mills (19) Vivacolor

- Vivacolor (2)

-

Electropolishing

- Electropolishing (24) Electroplating

- Electroplating (28) Engraving Machines / Laser Engraving

- Engraving Machines / Laser Engraving (42) Compressors

- Compressors (15) Magnetic Tumbler / Rotary Tumbler

- Magnetic Tumbler / Rotary Tumbler (63) Micromotors / Flex Shaft motors

- Micromotors / Flex Shaft motors (35) Ring Stretchers / Ring Bending Machines

- Ring Stretchers / Ring Bending Machines (8) Blasting

- Blasting (1) Grinding / Polishing / Brass

- Grinding / Polishing / Brass (23) Pickling Units

- Pickling Units (7) Draw Bench

- Draw Bench (9) Extraction unit

- Extraction unit (27) Ultrasonic Cleaners / Steam Jet Cleaners

- Ultrasonic Cleaners / Steam Jet Cleaners (29) Rolling Mills

- Rolling Mills (19) Vivacolor

- Vivacolor (2)

-

Electropolishing

- Electropolishing (24) Electroplating

- Electroplating (28) Engraving Machines / Laser Engraving

- Engraving Machines / Laser Engraving (42) Compressors

- Compressors (15) Magnetic Tumbler / Rotary Tumbler

- Magnetic Tumbler / Rotary Tumbler (63) Micromotors / Flex Shaft motors

- Micromotors / Flex Shaft motors (35) Ring Stretchers / Ring Bending Machines

- Ring Stretchers / Ring Bending Machines (8) Blasting

- Blasting (1) Grinding / Polishing / Brass

- Grinding / Polishing / Brass (23) Pickling Units

- Pickling Units (7) Draw Bench

- Draw Bench (9) Extraction unit

- Extraction unit (27) Ultrasonic Cleaners / Steam Jet Cleaners

- Ultrasonic Cleaners / Steam Jet Cleaners (29) Rolling Mills

- Rolling Mills (19) Vivacolor

- Vivacolor (2)

-

Manual rolling mill Agile Elite C110, PINK EDITION, Durston

Manual rolling mill Agile Elite C110, PINK EDITION, Durston -

Manual rolling mill R100LF, side-roulettes and reduction gear, O.M.O.

Manual rolling mill R100LF, side-roulettes and reduction gear, O.M.O. -

Mini rolling-mill for wedding rings, O.M.O.

Mini rolling-mill for wedding rings, O.M.O. -

Combi power rolling mill TUI C130, single sided, Durston

Combi power rolling mill TUI C130, single sided, Durston -

Combi power rolling mill TUI 130, double sided, Durston

Combi power rolling mill TUI 130, double sided, Durston -

Manual rolling mill Agile C130, single frame, Durston

Manual rolling mill Agile C130, single frame, Durston -

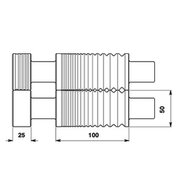

Manual rolling mill DRM C100 R, Durston

Manual rolling mill DRM C100 R, Durston -

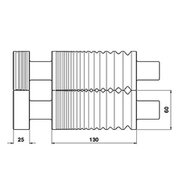

Manual rolling mill DRM C100 RE, Durston

Manual rolling mill DRM C100 RE, Durston -

Manual rolling mill DRM C130 RE, Durston

Manual rolling mill DRM C130 RE, Durston -

Manual rolling mill DRM C130 R without roulette, Durston

Manual rolling mill DRM C130 R without roulette, Durston -

Standard wire rolling mill DRM W100 E, Durston

Standard wire rolling mill DRM W100 E, Durston -

Standard wire rolling mill DRM W130 E, Durston

Standard wire rolling mill DRM W130 E, Durston -

Flat rolling mill DRM F100 RE, Durston

Flat rolling mill DRM F100 RE, Durston -

Flat rolling mill DRM F130 RE, Durston

Flat rolling mill DRM F130 RE, Durston -

Double rolling mill D2 130, Durston

Double rolling mill D2 130, Durston -

Double rolling mill D4 158, Durston

Double rolling mill D4 158, Durston

Rolling mills for sheet and wire

A rolling mill enables you to change the shape of your precious metal. For instance, when you roll a sheet, it becomes thinner and longer - the same applies when rolling wire. With a rolling mill you can thus modify the dimensions of your material and get closer to the final dimension in a way that is both faster and easier compared to forging, sawing, and filing your way to the desired size. A major advantage of rolling is not only saving time and effort but also achieving significant material savings.

Which rolling mill should I choose?

Achieving neat and uniform rolling of wire or sheet requires a sturdy rolling mill, and there are various types available. The choice of rolling mill depends on your needs. The most versatile rolling mill is the comb rolling mill, where you can roll both sheet and wire. In our range, there are also special rolling mills that, besides sheet and wire, have integrated profiles in the rollers, particularly suitable for, for example, producing wedding rings.

Furthermore, the rolling mills come in different sizes, crucial for the size of items you can roll. Therefore, the size of the rolling mills is also something to consider when choosing the rolling mill you need. In our range, you can find rolling mills with rollers ranging from 100 mm up to 158 mm in width. The combi rolling mill with 130 mm wide rollers is a versatile rolling mill with a good size, covering the needs of many workshops. The larger rolling mill models with separate wire and sheet rollers are robust rolling mills suitable for workshops with larger jewellery productions.

All our manual rolling mills have built-in reduction gears, providing smoother and easier rolling.

Maintenance of your manual rolling mill

All hand-operated rolling mills in our range are cast in one piece, making them incredibly robust. All bearings are self-lubricating and thus almost maintenance-free, ensuring the highest quality of robust and user-friendly rolling mills.

Although the rolling mills are virtually maintenance-free, you still need to take good care of them. Therefore, we recommend the following:

- Do not use cleaning agents on your rolling mill.

- Wipe the rolling mill rolls clean with a soft cloth before use.

- Lubricate the rollers if they will not be used for an extended period or if the rolling mill is located in a place with high humidity.

- Additionally, the gears on the side of the rolling mill should be lubricated once a year with gear grease.

By taking care of and maintaining your rolling mill, you are guaranteed a machine for life.

Power rolling mills for larger jewellery production

In our range, you will also find motorised power rolling mills for the professional goldsmith workshop, where there is a need for high capacity. These may involve strong wires, sheets, or thick plates for larger jewellery productions, where smooth and uniform rolling of precious metals is crucial for a professional result.

The power rolling mills come in compact combi models and large double rolling mills with a width of up to 130 mm. The motorised rolling mills have variable speed from 5-20 rpm. They are also quiet, have high performance, and can run forwards and backward. Additionally, the power rolling mills have a built-in emergency stop button and safety guards.

All our power rolling mills use 230V 1.1 kW power and do not require additional installation.

Mounting your rolling mills

For the best utilisation and effectiveness, your rolling mill should be mounted on a stable and solid surface. Small rolling mills can be mounted on a tabletop, thus saving space. However, larger rolling mills will require a more stable and floor-mounted stand. At Aktiv Guld, you will find a rolling mill stand that fits all manual rolling mills.

The power rolling mills are heavy machines that require solid and firm mounting. We also offer a sturdy table that fits all power rolling mills.

Durston Rolling Mills - quality since 1974

At Aktiv Guld, we have a wide selection of rolling mills from Durston, that are globally recognised for their production of manual and power rolling mills for goldsmiths and jewellery designers. Since its establishment in 1974, the core of Durston's business has been the development of rolling mills focusing on quality, detail, and durability. With a rolling mill from Durston, you can be sure to get a solid rolling mill that lasts a lifetime and guarantees a professional result time and time again.

If you're unsure which rolling mill to choose, please contact us, and we'll help you find the rolling mill that best suits your needs.